Digitalisation in metal casting operations requires 3 MAJOR PRE-REQUISITES

- Digital Mindset

- Operational Transparency

- Consistency in the transformation journey

As manufacturers, there are problems that are faced across the industry. In metal casting this is no difference. With #digitalization of metal casting operations you will be able to eliminate some of these obstacles faced in manual processes and operations and their controlling.

So as a metal casting manufacturer, what’s your biggest pain point? Likely its going to be:

- Inventory Control & Visibility

- OEE Machine Utilization

- Traceability of Production

- Real-time Scheduling

If you select any of the above on priority then you may have missed the point. All 4 items are equally important BUT when it comes to understanding the above bullet points in comparison to the items 1-3 above please focus on the essential requirement for managers and supervisors to CONSISTENTLY utilize their data and information gathered through digital solutions.

Because transitioning towards a digitalized ecosystem is more than just a toolset, it’s a complete (digital) mindset

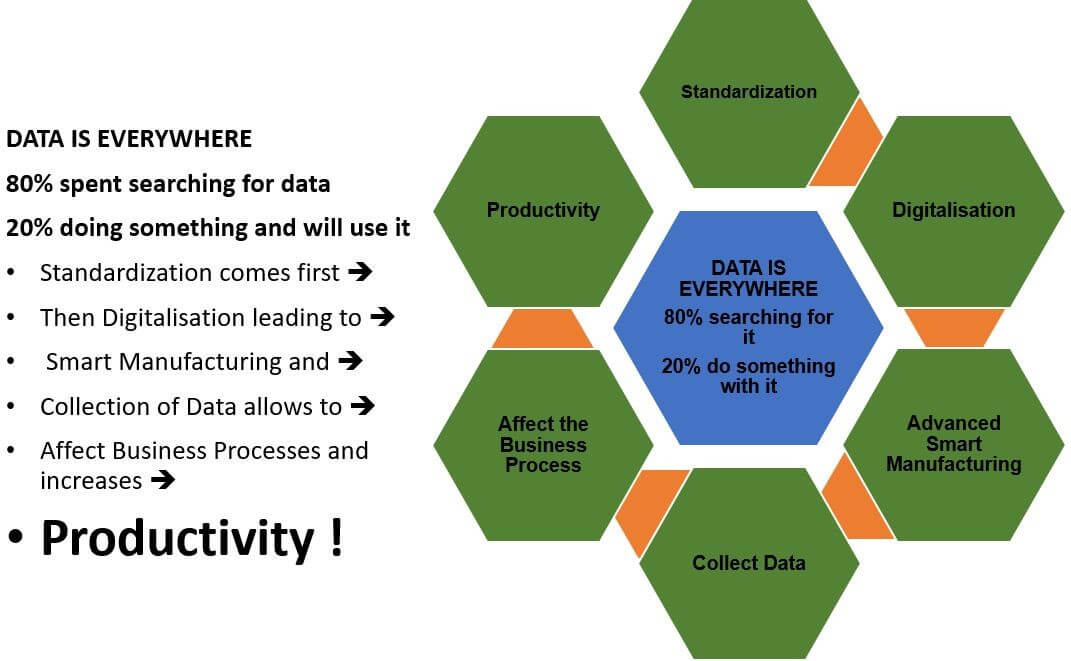

The main reason WHY this is the right approach lies in the fact that DATA IS EVERYWHERE

Your FOUNDRY is a treasure box of DATA. You just need to harvest it, put into a proper setup and ensure you follow through in your digitalisation efforts, after all its like running marathon.

In addition the classical 80/20 rule applies as well

While 80% spent searching for the data

Only 20% have it readily available and doing something with it