In many (steel) foundries, ironworks, steelworks the IT-support for the melting in contrast to other areas of production, is still a long way from achieving its full potential. Very often the level of industry is more or less on a “2.0” – infrastructure and very far away from the “Industry 4.0 or Foundry 4.0” – digitalization and deployment of cyber-physical system – concept.

In order to achieve the desired quality for melt-shop operations, continuous and discontinuous processes have to be synchronized and process parameters within the individual manufacturing steps have to be aligned to each other.

Why FRP®.melt can support YOUR melt-shop operations?

- The melt shop is THE MOST important part of a foundry / ironworks / steelworks

- It however comprises of up to 70% of total energy cost in a metal casting company

- The „melt process“ makes a foundry unique in manufacturing, it requires attention

- Evolutionary process inside the Melt Shop Area allows creation of databases

- The melting and alloying process is in many foundries a well protected company secret –> this special Know-How must be preserved in form of a Data Base and not in Excel or even paper

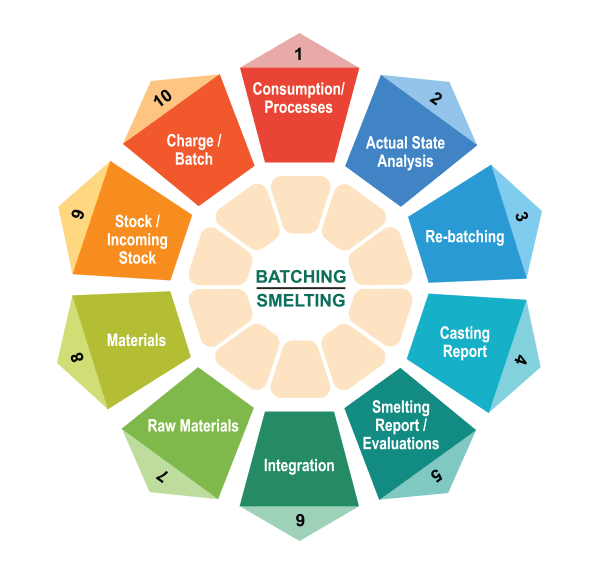

- FRP®.melt can be a standalone software package or fully integrated into the FRP® – suite of foundry resource planning solutions.

- MELT PROCESS PLANNING – FRP.melt delivers extensive melt process planning for all melt and treatment steps at charge, ladle and casting levels.

- ACCURATE CHARGE COMPOSITION AND POST CHARGE COMPOSITION – FRP®.melt optimizes the usage of materials, especially of expensive metals, by means of accurate (post) charge composition.

- PRELIMINARY COSTING – FRP®.melt enables preliminary costing to be carried out, calculating the requirements for scrap, alloying materials and metals.

- ONLINE SUPPORT – FRP®.melt provides online support for the smelter, reduces melt times significantly and thus increases melt capacity.

- ENERGY MANAGEMENT – FRP®.melt reduces energy consumption per ton and supports energy management at the point of highest consumption, which in turn leads to considerable cost savings.